Introduction

Steel detailing is an important step in the construction industry because it bridges the gap between design and manufacturing to enable the exact construction of steel structures. However, it is not without its difficulties. In this article, we will look at the most typical common challenges in steel detailing and offer practical strategies to overcome them, enabling for the effective completion of complicated projects.

Common Challenges in Steel Detailing

1. Drawings that are incomplete or inaccurate

The accompanying drawings and specifications serve as the foundation for any steel detailing job. Incomplete as well as incorrect documentation might result in costly problems throughout the project. However, Detailers must carefully study the original material, request clarification if needed, and convey any inconsistencies to project stakeholders.

2. Design Modifications

Changing the design once the detailed phase has begun might be difficult. These modifications might have an impact on structural integrity and necessitate rework. However, Detailers should create a simplified change management procedure to guarantee that design changes are incorporated quickly and accurately.

3. Communication Disruptions

Misunderstandings can lead to costly blunders, therefore effective communication is essential in steel detailing. It is critical to bridge communication gaps between architects, engineers, contractors, and detailers. Miscommunication problems may be avoided with regular meetings and a collaborative approach.

4. Adherence to codes and standards

Steel detailing projects must comply with several building codes and industry requirements. It is critical to ensure that every aspect conforms with these standards in order to avoid legal and structural concerns. Detailers should have a full awareness of the relevant rules and standards, and they should perform frequent inspections to ensure compliance.

5. Fulfilling Project Deadlines

Project schedules can be tight, and missing deadlines can have serious consequences. To keep projects on track, detailers must organize their work effectively, employ time-saving technologies and methods, and constantly assess their progress.

6. Quality Assurance

Rushing through the detailing process without performing extensive quality control checks might result in flaws that go undetected, resulting in structural concerns. Detailers should conduct stringent quality control systems, such as peer reviews and extensive inspections, to maintain high-quality standards.

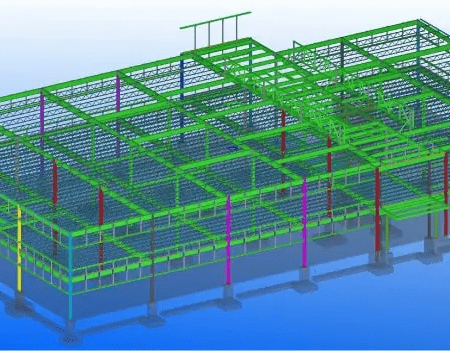

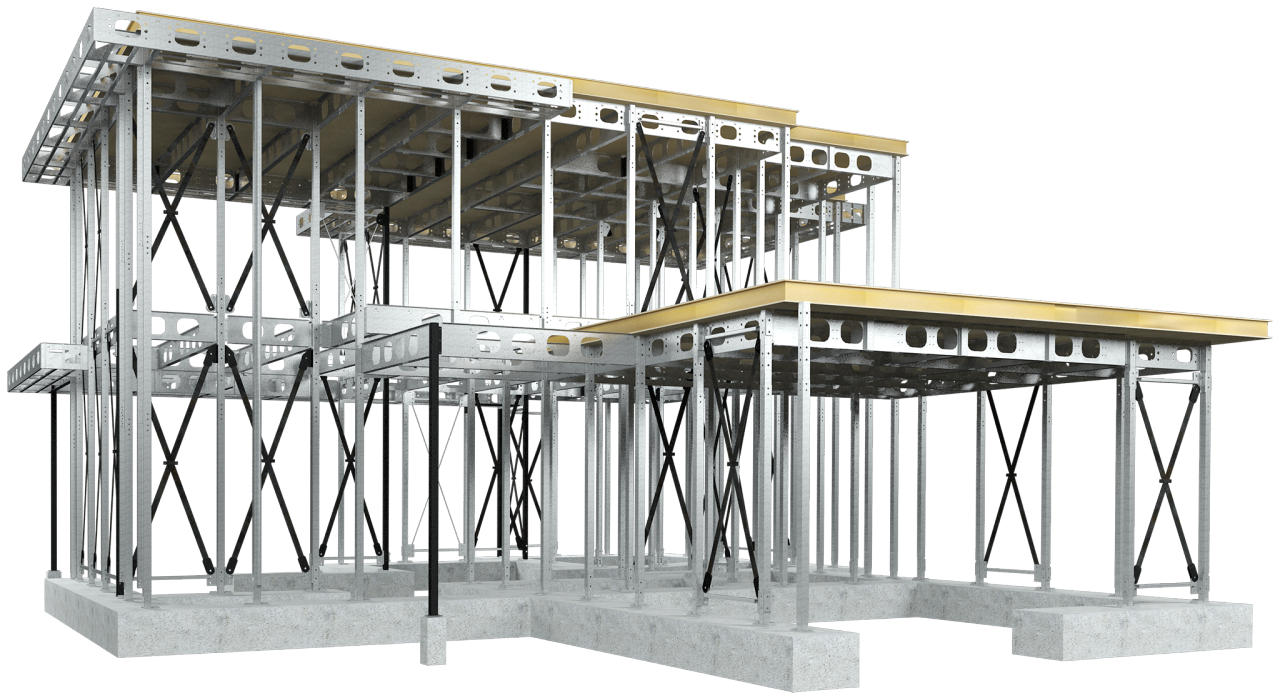

7. Clash Detection and 3D Modelling

Interference and disputes between various components might cause the construction process to be disrupted. Failure to discover and address these incompatibilities during the detailing process can result in costly rework and construction delays. Detailers can find and correct collisions earlier in the process by using 3D modelling and clash detection technologies.

8. Considerations for the Site

Every building site is different, with its own set of problems such as weather conditions, soil qualities, and access restrictions. Consequently, failure to address these site-specific characteristics might lead to fabrication and construction difficulties. In order to account for these factors, a thorough site investigation should be performed.

Overcoming Common Challenges in Steel Detailing

Detailers can use the following ways to address these typical issues:

Thorough study: Carefully study project documents and, if necessary, request clarification.

Change Management: To handle design changes efficiently, implement a well-structured change management approach.

Effective Communication: To avoid misunderstandings, maintain open channels of communication among project stakeholders.

Code Adherence: Maintain a thorough awareness of applicable rules and standards, and conduct frequent compliance reviews.

Efficient Time Management: Manage projects effectively by utilising time-saving techniques and practises in order to fulfil deadlines.

Quality Control: Implement stringent quality control measures to achieve the greatest degree of detail accuracy.

Clash Detection Tools: Use 3D modelling and clash detection tools early in the process to find and resolve issues.

Site Analysis: Conduct a comprehensive site investigation to account for any site-specific problems.

Conclusion

Steel detailing is a time-consuming and sophisticated procedure that is not without its difficulties. Nevertheless, detailers may assure the precision and success of their projects by identifying these typical hazards and employing effective techniques to overcome them. Firstly, paying attention to detail, communicating clearly, adhering to standards, and adopting technology are critical components in navigating the complexity of steel detailing while providing great outcomes in the construction sector.