Steel structures are the backbone of modern construction, providing incredible strength and flexibility for everything from skyscrapers to bridges. But the strength of these structures relies heavily on a crucial behind-the-scenes process: steel detailing.

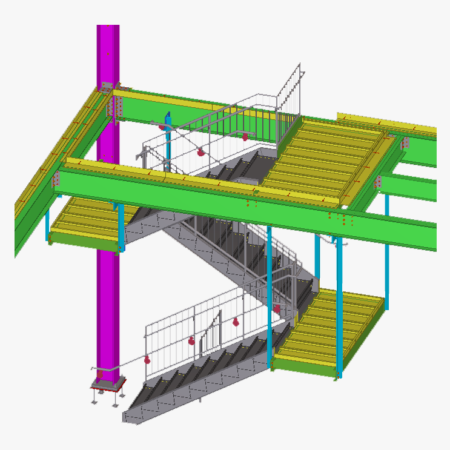

Steel detailers act as the bridge between the engineer’s vision and the physical construction. They transform engineering plans into meticulous shop drawings that specify every aspect of the steel components, from dimensions and cuts to weld sizes and bolt placements. This level of detail plays a vital role in ensuring the structural integrity of the final building.

Here’s how steel detailing services enhance structural integrity in five key ways:

- Accuracy Through Precision: Steel detailing involves meticulous attention to detail. Detailers use advanced software to create highly precise drawings that leave no room for misinterpretation. This ensures that every steel member is fabricated and assembled according to the engineer’s exact specifications. Reduced errors in measurements and connections translate directly into a stronger, more reliable structure.

- Optimized Connections: Connections are the most critical points in any steel structure, as they bear the brunt of the load. Steel detailers have expertise in designing and detailing these connections to maximize strength and ensure they can withstand the forces they’ll be subjected to. This might involve specifying the type, size, and quantity of welds or bolts needed for each connection.

- Clash Detection and Resolution: With complex projects involving multiple disciplines, there’s always a risk of clashes between different building elements. Steel detailing services use sophisticated software to identify potential clashes between steel components, mechanical systems, and other building elements before construction even begins. This proactive approach prevents costly delays and rework on-site, ensuring a smooth and efficient construction process.

- Material Efficiency: Steel detailing isn’t just about strength; it’s also about optimizing material usage. Detailers can analyze the structural loads and design steel members to be as efficient as possible, minimizing excess material. This not only reduces costs but also contributes to a more sustainable construction process.

- Streamlined Fabrication and Assembly: Detailed shop drawings provide clear instructions for steel fabricators and erectors. This ensures that the steel components are manufactured and assembled correctly on-site. Proper detailing also facilitates efficient sequencing of the construction process, minimizing delays and disruptions.

Beyond the Blueprint: The Ripple Effect of Steel Detailing

The benefits of steel detailing extend far beyond the structural integrity of the building itself. Here are some additional advantages:

- Improved Safety: Precise detailing reduces the risk of errors during fabrication and erection, leading to a safer work environment for construction workers.

- Reduced Costs: By minimizing errors, optimizing material usage, and streamlining construction, steel detailing helps to keep project costs under control.

- Enhanced Schedule Adherence: Clear and detailed shop drawings ensure a smooth workflow, preventing delays due to confusion or rework.

- Better Communication: Steel detailing acts as a common language between engineers, fabricators, and erectors, fostering better communication and collaboration throughout the project lifecycle.

In conclusion, steel detailing services play an indispensable role in ensuring the structural integrity of steel buildings. By providing a bridge between design and construction, steel detailers transform engineering concepts into safe, reliable, and cost-effective structures. The next time you marvel at a towering skyscraper or a graceful bridge, remember the invisible backbone – the meticulous work of the steel detailers – that made it possible.

While steel is an excellent structural material, it can transmit sound vibrations. Integrating acoustic insulation or composite materials in steel decks can enhance soundproofing in buildings. Brainstorm Infotech is headquartered in Bengaluru, the start-up capital of India. It has carved a niche for itself in the field of structural steel detailing and allied services with a credit of completing over 1250 projects so far. We started small with a team of five professionals in 2010 but have earned the trust and respect of our clients that has led to long-standing associations.visit our site:https://www.brainstorminfotech.co.in//